1. Blade Material

The choice of blade material is pivotal in determining the performance and longevity of a slicing knife. High-quality slicing knives often utilize premium stainless steel, carbon steel, or even alloys designed for optimal sharpness and durability.

Stainless Steel: Stainless steel blades are renowned for their corrosion resistance and low maintenance. They resist staining and rust, making them ideal for kitchen environments. High-carbon stainless steel combines the benefits of both stainless steel and the hardness of carbon steel, allowing for better edge retention without sacrificing corrosion resistance.

Carbon Steel: Carbon steel knives, while more prone to rust, can achieve a razor-sharp edge that many chefs favor. They require more maintenance, including regular oiling and hand washing, but offer unparalleled cutting performance when well cared for.

High-Performance Alloys: Some modern slicing knives are made from advanced materials like VG-10 or S35VN. These steels provide an exceptional balance of sharpness, edge retention, and ease of sharpening, appealing to both home cooks and professionals.

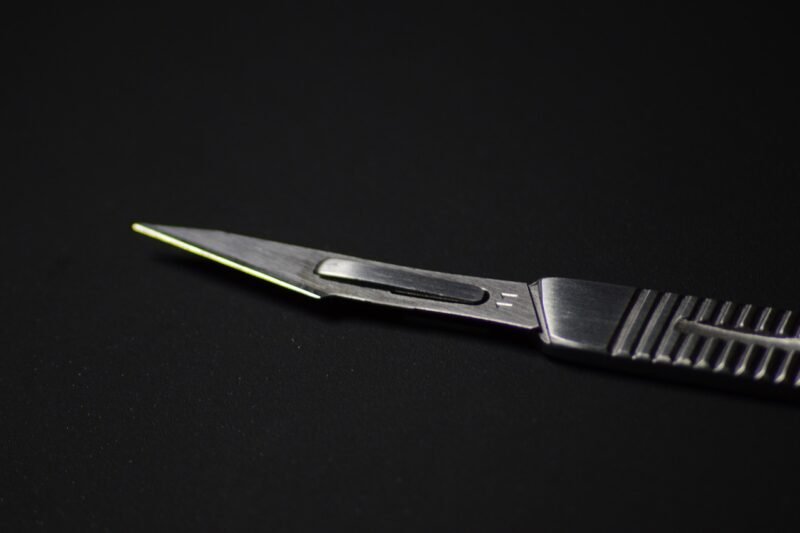

2. Blade Design

The design of the blade plays a crucial role in the efficacy of a slicing knife. A well-designed blade enhances both the aesthetics and functionality of the knife.

Length and Width: High-quality slicing knives typically range from 8 to 12 inches in length. A longer blade allows for more extended strokes while slicing meats or bread, resulting in cleaner cuts. A wider blade provides stability and surface area, essential for supporting food during slicing.

Edge Profile: The blade’s edge can be straight, serrated, or a combination of both. Straight edges are ideal for clean cuts of meat and fish, while serrated edges excel in slicing through bread without crushing the loaf. A high-quality slicing knife often features a slight curve for rocking motions, which is especially useful for finely slicing herbs or softer ingredients.

Spine and Tip: A thicker spine contributes to stability, while a tapered tip allows for intricate tasks such as detailed slicing or trimming. Tourist cervical to the design, a well-balanced knife not only provides comfort during use but also enhances precision.

3. Handle Comfort and Material

A knife is only as good as its handle. The grip and overall ergonomics are vital, as slicing often involves repetitive motions. A comfortable handle minimizes fatigue and ensures control over the knife’s movements.

Material Choices: Handles can vary from wood, plastic, to metal, or composite materials. Wood handles offer a classic look, with options like rosewood or walnut providing aesthetic appeal and natural grip textures. However, they require proper care to prevent moisture damage.

Synthetic Materials: High-quality slicing knives often use synthetic materials like G-10, Micarta, or thermoplastic elastomers. These materials provide superior grip, moisture resistance, and durability. They often feature ergonomic designs that conform to the hand, providing a secure hold even when wet.

Design Elements: A full tang design (where the blade extends through the handle) enhances balance and strength. Additionally, some handles come with texturing or grooves that further enhance grip security. A reduction in slip significantly improves precision and safety while slicing.

4. Balance and Weight

The balance and weight of a slicing knife significantly contribute to its performance. A well-balanced knife feels natural in hand, allowing for better control during intricate slicing tasks.

Balance Point: The ideal balance point should be just in front of the handle. This positioning allows for smooth motions regardless of slicing technique. A handle-heavy knife might tire the wrist during prolonged slicing, while a blade-heavy knife can be unwieldy and hard to control.

Weight Considerations: A heavier knife is ideal for cutting through tougher materials like meat, lending more power to each slice. Conversely, a lightweight knife excels in precision tasks, allowing for swift movements without excessive effort. Ultimately, personal preference plays a significant role; chefs should choose a knife that feels comfortable and effective in their hands.

5. Maintenance and Sharpening Requirements

Maintenance plays an essential role in ensuring the longevity of a slicing knife. A high-quality knife should be easy to maintain and sharpen, allowing users to keep the blade in optimal condition.

Sharpening: The ability to maintain sharpness is crucial. High-carbon and stainless-steel blades can often be honed with honing rods or sharpened using whetstones, while others may require specific tools. A knife with a Rockwell hardness rating between 58 and 62 balances sharpness with durability.

Ease of Maintenance: Maintenance includes not just sharpening but also cleaning. High-quality slicing knives should be easy to clean and resistant to staining. Ideally, a knife should be hand-washed to maintain the integrity of both the blade and the handle material.

Storage Solutions: Proper storage also contributes to a knife’s longevity. High-quality slicing knives often come with protective sheaths or cases, preventing damage to the blade and thereby extending its lifespan. Magnets or knife blocks can also provide convenient and safe storage options that protect the blade’s edge from damage.

In summary, a high-quality slicing knife is not merely a tool but an essential component of any culinary environment. By focusing on superior blade materials, thoughtful design, ergonomic handle constructions, balanced weight, and maintenance considerations, one can find a slicing knife that not only elevates cooking performance but also offers joy and satisfaction with every use.